In commercial and project‑grade installations — hotels, serviced apartments, large residential developments, conference rooms — choosing the right curtain track for heavy curtains is critical. A standard lightweight track may work initially, but once heavy fabrics (blackout drapes, velvet, layered fabrics) are installed, you’ll quickly run into problems: sagging, noisy gliding, premature wear, or hardware failure.

This guide helps you select the best curtain track for heavy curtains, with clear evaluation criteria, technical parameters, and best‑practice recommendations — tailored for B2B buyers, contractors, and procurement teams.

1. Why Heavy Curtains Demand a Heavy‑Duty Curtain Track

Heavy curtains — such as blackout drapes, layered thermal curtains, velvet or lined drapes — often weigh 15–30 kg per meter or more, depending on fabric weight, lining, curtain width and fullness. Alibaba+1

Using a standard track (light aluminum or plastic) can lead to multiple issues:

- Sagging or bowing in the center of the track under weight.

- Difficulty drawing or sliding curtains; gliders may stall under load.

- Brackets or fixings loosening over time, risking safety failures — especially in high‑turnover environments like hotels.

- Premature wear of gliders, increased noise, poor user experience.

Therefore, for heavy curtains, you must choose tracks and systems built with higher structural integrity, stronger materials, and robust load‑bearing specs.

2. Key Criteria for Choosing the Best Track for Heavy Curtains

When evaluating curtain tracks for heavy drapes, consider at least the following criteria:

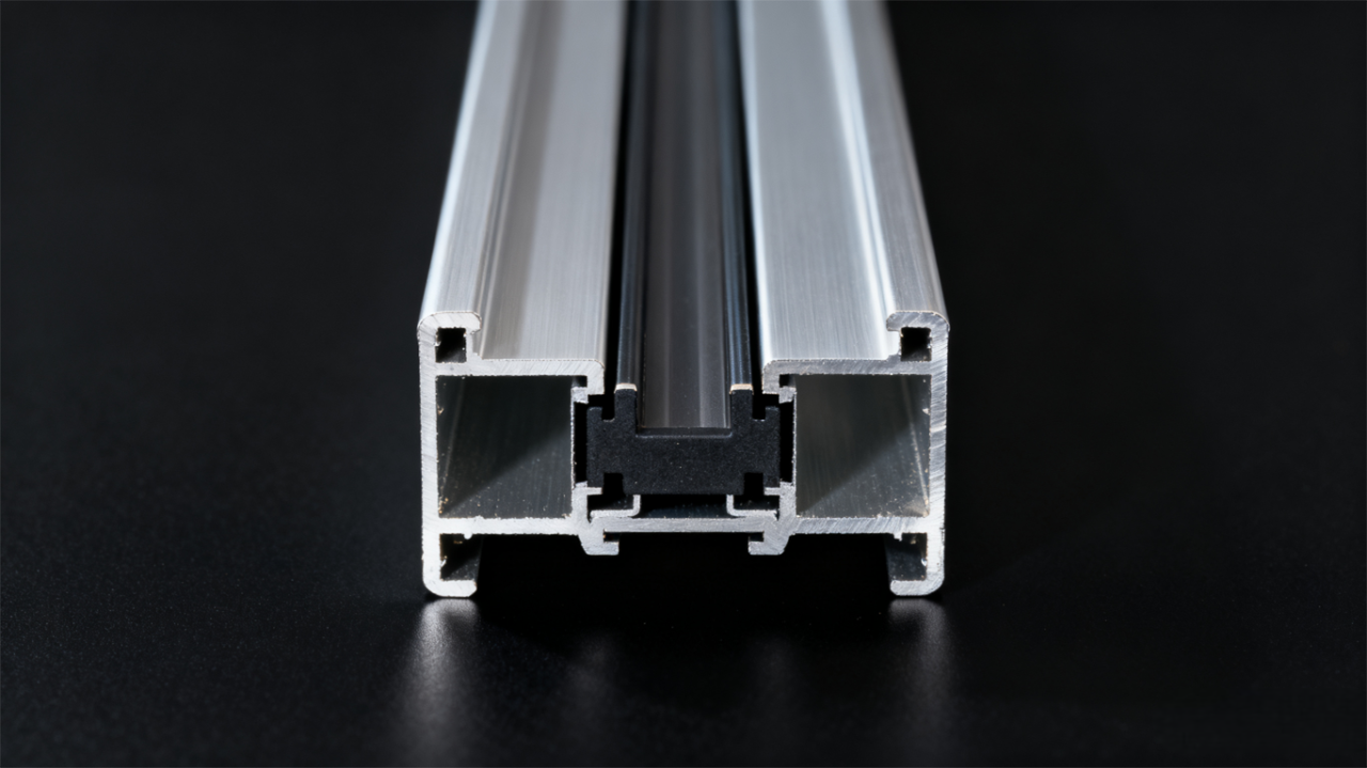

2.1 Material & Profile Strength

- Preferred material: Extruded aluminum alloy (≥ 6063), or galvanized/steel track. Aluminium offers good strength-to-weight ratio, corrosion resistance, and is industry standard for commercial tracks.

- Profile wall thickness: For heavy-duty, look for 1.5–2.5 mm wall thickness (or equivalent structural rigidity) to resist bending under load; some premium tracks go up to 2.0+ mm.

2.2 Load Capacity & Glider/Carrier Strength

- Track load rating: Should support at least 15–25 kg/meter for heavy curtains; for very heavy or multiple-layered curtains, consider tracks rated ≥ 30 kg/meter.

- Number and quality of gliders/carriers: More gliders per meter — ideally 8–12 gliders or rollers per meter — improves weight distribution and smooth movement.

- Fixed end‑stop and metal glider hardware (metal wheels/hooks) over plastic hooks to handle repeated draw cycles.

2.3 Mounting & Bracket System

- Brackets: Steel or reinforced alloy brackets, spaced appropriately — heavy curtains often require bracket spacing ≤ 500 mm (20 in) to ensure load is evenly supported.

- Fixing type: Ceiling‑mount or wall‑mount, depending on structure; for highest load, ceiling‑mount with anchors into joists or concrete is preferred. Sew What?

- For spans over 3–4 m: intermediate support or stiffener bars recommended to prevent sagging.

2.4 Operating Mechanism & Durability

- Gliders or runners with ball‑bearing wheels or low‑friction carriers provide smoother glide under heavy load. Sew What?

- Surface finish: Powder-coated or anodized aluminum (or galvanized steel) for corrosion resistance and longevity — important in humid or coastal environments.

- Optional: motorized or cord-drawn systems, particularly for wide windows or automated operation, though manual strong glider systems suffice in many B2B projects. Sew What?

2.5 Compliance & Quality Standards

- Look for tracks compliant with commercial-grade standards (e.g. ISO / EN standards, load testing, cycle testing for 20,000+ open/close cycles) to ensure reliability.

- Certifications like ISO 9001, fire‑resistant coatings, REACH compliance may be required in some projects, especially hospitality or institutional settings.

3. Recommended Heavy-Duty Curtain Tracks & Their Strengths

Here are some examples of curtain track systems known for handling heavy curtains — useful when you source for projects, negotiate with suppliers, or design specifications:

- CheeryCurtains CHRY4120 Heavy Duty Aluminum Curtain Track — wall or ceiling mount, aluminum alloy, supports up to ~80 kg per track section. Good for single or double tracks, suitable for heavy drapes or layered curtains.

- SewWhat Inc. Silent Steel Series 280 — galvanized steel, designed for theater‑grade or heavy drapes, supports 20–50 lbs per foot of track (≈ 30–75 kg per meter, depending on model). Good for very heavy curtains, theatrical or hotel installations. Sew What?

- Qurails 5600 / 4100 Series — extruded aluminum ceiling or wall‑mounted track, smooth gliding, capable for light to heavy curtains, often used in residential and commercial settings.

- Generic heavy-duty aluminium/steel curtain tracks from reputable manufacturers/suppliers offering reinforced gliders, metal carriers, powder-coating, heavy-load specs (30–50kg per meter), suitable for blackout, layered or velvet curtains.

Recommendation Rule: For typical hotel or apartment heavy drapes (lined blackout or medium-weight fabric), choose a track rated ≥ 25 kg/meter with ≥ 10 gliders per meter. For extra-heavy curtains (multi-layer, velvet, wide-span), consider steel‑based tracks like Silent Steel 280 or similarly rated tracks.

4. Installation & Specification Best Practices for Heavy-Duty Tracks

To ensure longevity and proper functioning in B2B projects, follow these best practices:

- Bracket Spacing: For heavy curtains, maintain bracket spacing ≤ 50 cm (20 in) — closer spacing reduces bending moment and distributes load.

- Double Glider Density: Use 8–12 gliders per meter — dense glider distribution prevents concentrated load per runner, reduces wear.

- Fixed End‑Stops: Always use fixed end‑gliders at both ends to prevent curtains from sliding off track during draw cycles.

- Use High‑Quality Carriers / Rollers: Prefer metal gliders or ball‑bearing rollers over plastic — ensures smoothness and durability under heavy load.

- Support for Long Spans / Curves: For tracks longer than ~3 m or for curved tracks, include intermediate support, stiffener bars, or additional brackets to prevent sagging.

- Surface Finish for Longevity: Use powder-coated, anodized aluminum or galvanized steel to resist corrosion — especially important in humid, coastal, or high-traffic environments.

- Load Rating Margin: Always choose track rated for 20–30% more weight than expected curtain weight — this safety margin accommodates curtain movement, additional lining, or future heavier curtains.

5. Common Mistakes & Risks — What to Avoid When Selecting a Track

- Using lightweight PVC or thin plastic tracks for heavy curtains — will often lead to sagging, track bending, glider failure.

- Inadequate bracket spacing or weak fixings — especially with wall mounting on drywall without proper anchors/studs — can cause pulling out or collapse under weight.

- Sparse glider distribution — too few gliders lead to stress concentration, uneven fabric drape, noisy operation.

- Ignoring total curtain weight: layered curtains (e.g. blackout + sheer), thermal lining, or extra width significantly increase load — track must be sized accordingly.

- Skipping maintenance — heavy-duty tracks still require periodic inspection: lubricate gliders, check brackets, ensure smooth operation.

6. Recommendations: Which Curtain Track to Use for Which Scenario

| Scenario / Curtain Type | Recommended Track Type & Specs | Why |

|---|---|---|

| Medium-weight blackout curtains, standard windows (width ≤ 3 m) | Heavy-duty aluminum track, min 25 kg/m, glider density ≥ 10/m, bracket ≤ 50 cm | Good balance—cost-effective, smooth operation, durable |

| Wide windows / floor-to-ceiling curtains / double-layer drapes | Steel or heavy aluminum track, 30–50 kg/m rating, metal gliders, fixed end-stops | Higher load capacity + longevity for frequent use |

| Velvet, lined curtains, hotel/apartment project, frequent draw cycles | Industrial/ theater-grade track (e.g. box-shaped steel rail), 50+ kg/m capacity, ball-bearing runners | Handles heavy load, high durability, ensures smooth glide |

| Long spans (>3 m), curves, multiple rooms/units | Modular heavy-duty tracks with connectors, intermediate supports, corrosion-resistant coating | Stability over time, less maintenance, avoids sagging & failure |

Conclusion

Selecting the best curtain track for heavy curtains is crucial for commercial and project installations. Heavy fabrics such as blackout drapes, layered curtains, or velvet require tracks with strong materials, high load capacity, dense glider distribution, and secure mounting. Aluminum or steel tracks with reinforced brackets and ball-bearing gliders provide smooth operation, long-term durability, and professional appearance.

For B2B projects — hotels, serviced apartments, or multi-unit developments — always consider bracket spacing, end stops, and glider quality. Leaving a 20–30% safety margin over expected curtain weight ensures reliable performance and reduces maintenance.

By choosing the right heavy-duty track and following installation best practices, contractors and suppliers can guarantee a durable, smooth-operating curtain system that meets commercial standards, satisfies end users, and minimizes long-term issues.

Next step: evaluate your project’s curtain weight, select an appropriate track system, and follow installation guidelines to achieve professional results.