Aluminum Profiles

Our aluminum profiles offer lower installation costs and greater design flexibility, while their excellent strength and durable surface help you achieve reliable performance and long-term value.

Need a complete curtain installation solution or custom processing? Contact our team to get high-quality aluminum profiles tailored to your needs.

-

Aluminum Profiles

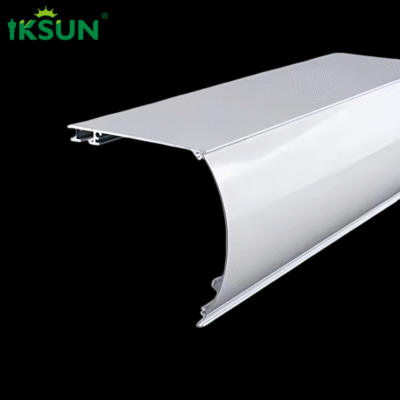

IKSUN Factory can customize powder paint polishing extruded curtain fittings bottom railing window aluminum profiles

Rated 0 out of 5Read more -

Aluminum Profiles

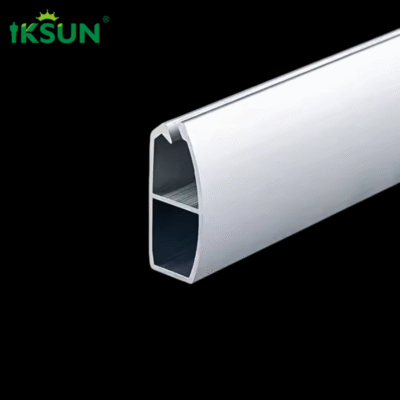

IKSUN Factory Wholesale Quality Wholesale Powder Coated Window Bottom Rail Aluminum Profile Accessories By ZGP

Rated 0 out of 5Read more

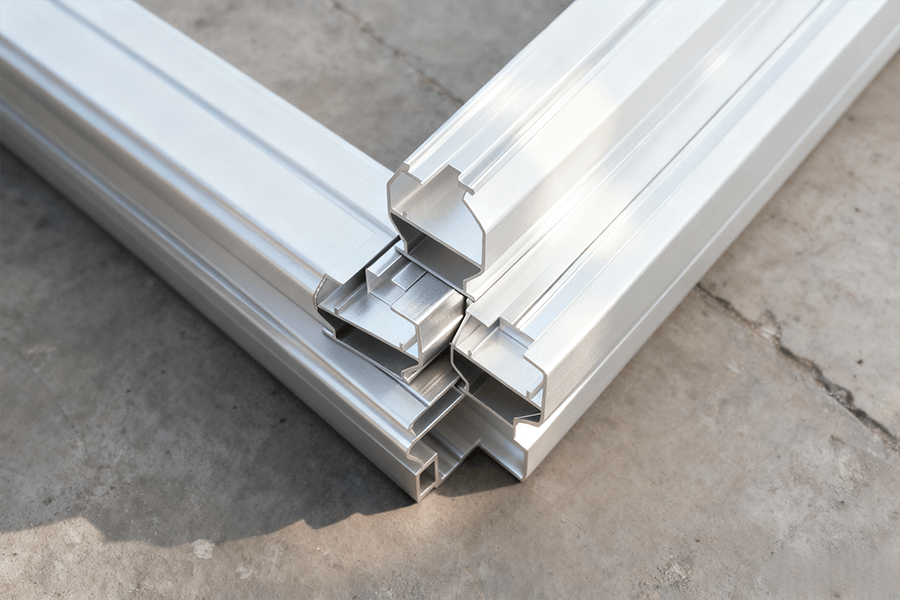

Aluminum Profiles Guide

Explore our professional aluminum profiles, designed for industrial, commercial, and residential applications. From T-slot and L-shaped profiles to custom extrusions, our high-quality aluminum profiles provide strength, durability, and precision for frames, curtain tracks, structural assemblies, and modular systems.

What is aluminum profiles?

Aluminum profiles are specially shaped aluminum extrusions used in construction, furniture, electronics, and industrial applications. They are produced by pressing heated aluminum through a die to create various cross-sectional shapes, such as T-slot, L-shape, or rectangular tubes. Lightweight, durable, corrosion-resistant, and easy to assemble, aluminum profiles are ideal for curtain tracks, frames, and structural components. Using aluminum profiles enhances stability and simplifies installation in both residential and commercial projects.

What are the types of aluminum profiles?

Aluminum profiles come in various types, designed for different applications:

- T-slot profiles:commonly used for frames, workstations, and modular assemblies.

- L-shaped and U-shaped profiles:ideal for corner supports, brackets, and edging.

- Rectangular and square tubes:widely used for structural components and furniture frames.

- Round and oval profiles:often applied in pipes, rails, and decorative elements.

- Specialty or custom profiles:tailored shapes for specific industrial or architectural needs.

Aluminum profiles are lightweight, durable, corrosion-resistant, and easy to assemble, making them suitable for construction, furniture, electronics, curtain tracks, and more.

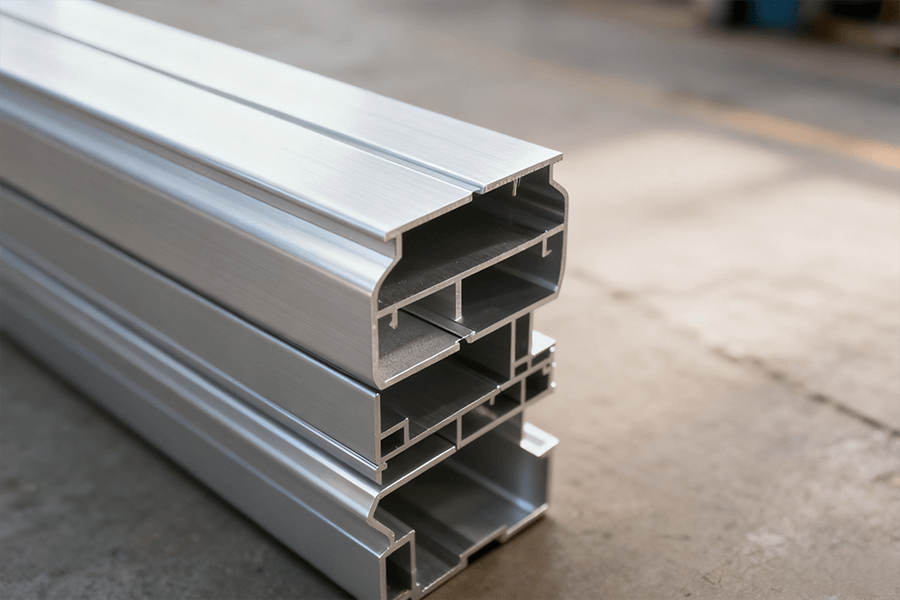

How to extrude aluminum profiles?

Aluminum profiles are extruded by heating aluminum billets and forcing them through a shaped die under high pressure. This process creates continuous profiles in various cross-sectional shapes, such as T-slot, L-shape, or rectangular tubes. Extrusion allows for precise dimensions and smooth surface finishes, making it ideal for construction, frames, and curtain tracks.

How to join aluminum profiles?

Aluminum profiles can be joined using screws, brackets, connectors, or specialized T-slot fasteners. For modular assemblies, connectors and corner brackets provide strong, adjustable joints without welding. Proper joining ensures stability and durability in furniture, frames, and industrial structures.

How to make aluminum profiles?

Making aluminum profiles involves the extrusion process: first, aluminum is heated and pressed through a die to form the desired shape. After extrusion, profiles are cooled, stretched for straightness, and cut to length. Additional surface treatments, like anodizing or powder coating, can enhance durability and appearance.

How to cut aluminum profiles?

Aluminum profiles can be cut using saws with carbide-tipped blades, CNC machines, or laser cutters, depending on precision requirements. Always measure accurately, secure the profile, and use proper safety equipment. Cutting profiles to exact lengths is essential for proper assembly and structural integrity.