1. Commercial Curtain Track Systems: A B2B Perspective

In commercial construction and interior fit-out projects, curtain track systems function as high-frequency mechanical components, not decorative hardware. Their performance directly affects:

- Safety compliance

- Daily operational efficiency

- Maintenance workload

- End-user satisfaction

For architects, project managers, and procurement specialists, the wrong curtain track specification can lead to structural failure, excessive noise, or costly retrofits after handover.

This guide explains how to choose the right curtain track system for commercial projects using engineering logic, procurement standards, and real-world application data.

2. Commercial vs Residential Curtain Track Systems

Understanding the distinction is essential for avoiding mis-specification.

| Criteria | Residential Track | Commercial Track |

|---|---|---|

| Daily operation | Low | High |

| Load tolerance | 5–10 kg/m | 15–60 kg/m |

| Service life | 3–5 years | 10–20 years |

| Compliance | Minimal | Fire & safety regulated |

| Maintenance | Occasional | Scheduled |

Commercial curtain tracks are designed for continuous operation, often exceeding 20,000 open-close cycles per year in hospitality and healthcare environments.

3. Load Engineering: How to Calculate the Correct Track Capacity

Step 1: Curtain Weight Calculation

Professional projects should calculate curtain weight using:

Fabric weight (gsm) × Curtain width (m) × Curtain height (m)

Example:

- Fabric: 320 gsm blackout

- Size: 6 m × 3 m

- Total fabric weight ≈ 5.8 kg

- With lining & accessories → ~7.5 kg

Step 2: Safety Factor

Commercial best practice applies a 1.2–1.5 safety coefficient.

Recommended track capacity:

- Minimum: 12–15 kg

- Ideal for long-term use: 20 kg+

4. Track Material and Structural Performance

Aluminum Alloy Curtain Tracks

Most commercial projects specify aluminum due to corrosion resistance and structural stability.

Recommended grades:

- 6063-T5 (standard commercial)

- 6061-T6 (high-load, long-span)

Key technical parameters:

- Wall thickness ≥ 1.2 mm

- Anodizing ≥ 10 μm

- Straightness tolerance ≤ 1/1000

Steel or Reinforced Curtain Tracks

Used in:

- Hospitals

- Auditoriums

- Industrial buildings

Advantages:

- Load capacity up to 60 kg/m

- Minimal deformation under long spans

Trade-off:

- Higher weight

- More complex installation

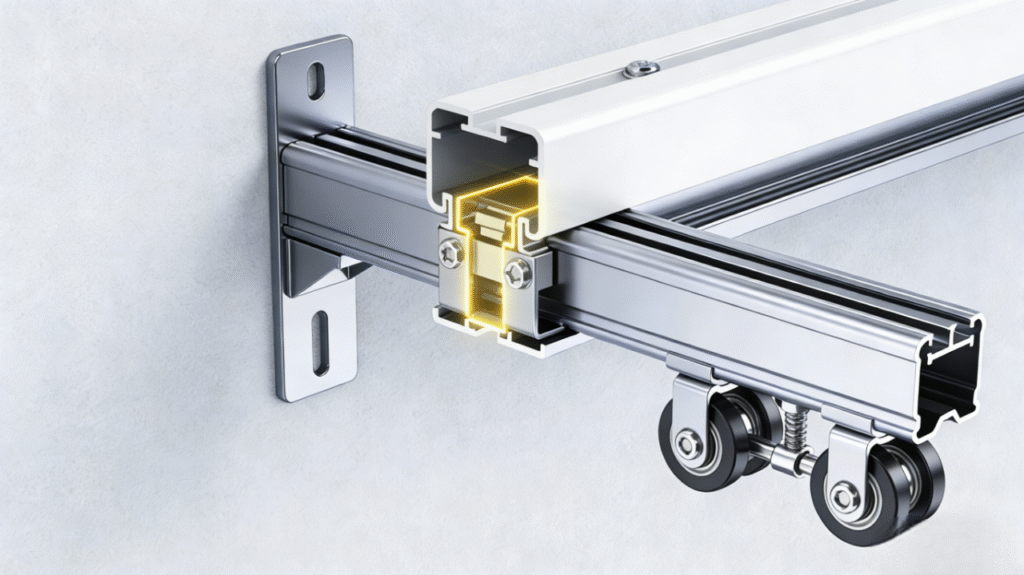

5. Curtain Track Profile Design and Roller System

Track performance is determined not only by material, but by profile geometry.

Key design factors:

- U-channel vs enclosed rail

- Slot width consistency

- Roller-to-track contact surface

Roller Specifications to Evaluate

- Bearing type: stainless steel / POM composite

- Friction resistance: ≤ 0.05

- Noise output: ≤ 25 dB

Low-quality rollers are the primary cause of operational noise and jamming in commercial spaces.

6. Manual or Motorized Curtain Track Systems?

Manual Curtain Track Systems

Best suited for:

- Budget-controlled projects

- Short spans (<5 m)

- Low-frequency usage areas

Professional requirements:

- Smooth glide under full load

- Anti-derailment runner design

- End-stop impact resistance

Motorized Curtain Track Systems

Increasingly specified in:

- Hotels

- Conference centers

- Smart office buildings

Key technical indicators:

- Rated torque matched to curtain weight

- Operating noise ≤ 35 dB

- IP20–IP44 protection

- Control integration: BMS / Zigbee / RF / Dry contact

Motorized systems significantly reduce manual wear and operational inconsistency in large-scale projects.

7. Fire Safety and Regulatory Compliance

Commercial curtain track systems must comply with local fire and safety regulations, especially in public buildings.

Commonly required standards:

- NFPA 701 – Flame resistance (US)

- EN 13501-1 – European fire classification

- BS 5867 – Curtain and track safety (UK)

- ASTM E84 – Surface burning characteristics

Tracks should be:

- Non-combustible

- Structurally stable under heat exposure

- Compatible with fire-retardant fabrics

8. Installation Conditions and Fixing Systems

Ceiling-Mounted Curtain Tracks

Advantages:

- Clean architectural appearance

- Even load distribution

Technical checks:

- Ceiling substrate strength

- Anchor pull-out resistance

- Expansion allowance for long spans

Wall-Mounted or Suspended Tracks

Used when:

- Ceiling conditions are limited

- Retrofit projects are required

Ensure:

- Bracket spacing ≤ 800 mm

- Load transfer to structural elements

9. Acoustic Performance in Commercial Environments

In hotels, hospitals, and offices, noise from curtain movement is a critical comfort issue.

Look for:

- Soft polymer runners

- Shock-absorbing end stops

- Anti-vibration mounting clips

Poor acoustic performance often results in negative guest feedback and operational complaints.

10. Maintenance Strategy and Lifecycle Cost Analysis

For B2B buyers, the real cost lies in maintenance and replacement, not purchase price.

Evaluate:

- Expected service life (≥15 years)

- Spare parts availability

- Ease of runner replacement

- Cleaning and lubrication requirements

A professionally specified track system reduces:

- Downtime

- Labor costs

- Post-installation disputes

Conclusion

Choosing the right curtain track system for commercial projects is a technical decision with long-term operational impact. By focusing on load engineering, material quality, compliance standards, acoustic performance, and lifecycle cost, B2B buyers can ensure reliable performance across diverse commercial environments.

A well-selected commercial curtain track system enhances safety, durability, and user experience—while protecting project budgets and brand reputation over time.