1. Why Uneven Walls Are a Critical Issue in Commercial Curtain Track Installation

In commercial and contract environments, uneven walls are the rule, not the exception. Common causes include:

- Concrete shrinkage and formwork deviation

- Masonry tolerance accumulation

- Renovation over existing finishes

- Wall panel misalignment

- Structural settlement

In B2B projects—such as hotels, hospitals, offices, and public buildings—curtain tracks must meet functional, safety, and aesthetic standards simultaneously. An uneven wall can lead to:

- Track misalignment and binding

- Uneven curtain movement

- Increased roller wear

- Noise complaints

- Anchor fatigue and failure

Professional installation is not optional—it is a requirement.

2. B2B Search Intent Behind “How to Install Curtain Tracks on Uneven Walls”

When professionals search for this topic, they are typically looking for:

- Installation methods that compensate for wall irregularities

- Acceptable flatness tolerances

- Hardware solutions for non-plumb surfaces

- Long-term performance under daily use

- Compliance with commercial building standards

This guide addresses those needs directly.

3. Assessing Wall Unevenness Before Installation

3.1 Measurement Methods Used in Professional Projects

Before installing any curtain track, wall conditions must be assessed using objective measurement tools, not visual judgment.

Recommended tools:

- Laser level (±1.5 mm / 10 m accuracy)

- 2 m straightedge

- Feeler gauge set

- Digital caliper (for shim thickness)

3.2 Acceptable Tolerances (Industry Reference)

| Wall Deviation | Professional Assessment |

|---|---|

| ≤ 2 mm / 2 m | Acceptable, no correction required |

| 2–5 mm / 2 m | Minor correction recommended |

| 5–10 mm / 2 m | Mandatory leveling solution |

| > 10 mm / 2 m | Structural correction advised |

Key Principle: Curtain tracks should never be used to “correct” wall defects. They must be installed on a properly leveled reference plane.

4. Selecting the Right Curtain Track System for Uneven Walls

4.1 Track Material Considerations

For uneven walls, track rigidity matters more than aesthetics.

Recommended materials:

- Extruded aluminum alloy 6063-T5

- Yield strength: ≥ 160 MPa

- Deflection: < 1.5 mm per meter under 10 kg load

Avoid:

- Thin-gauge steel tracks

- Plastic tracks

- Decorative residential-grade rails

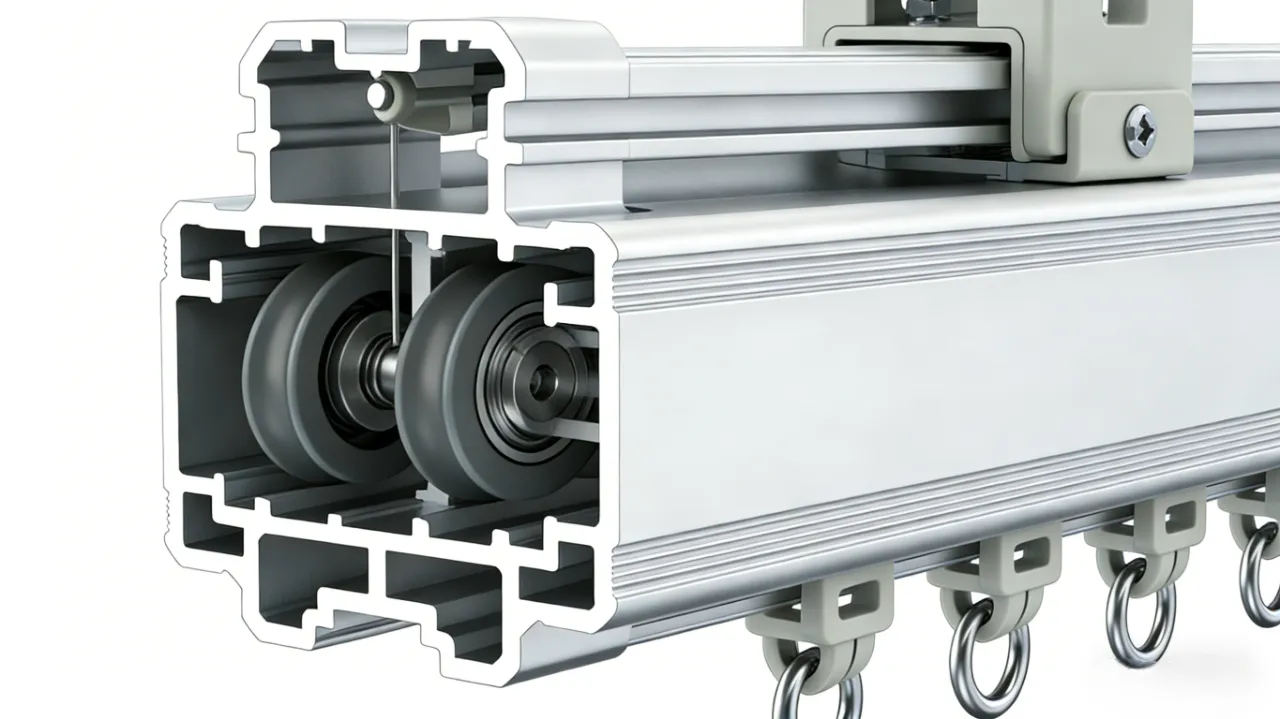

4.2 Mounting Bracket Design

For uneven walls, use adjustable or offset brackets:

- Adjustment range: ±10 mm minimum

- Slot length: ≥ 15 mm

- Load rating: ≥ 20 kg per bracket

These allow fine alignment without stressing anchors.

5. Professional Installation Methods for Uneven Walls

Method 1: Shim-Based Leveling (Most Common)

Best for: Minor to moderate wall irregularities (≤ 8 mm)

Materials:

- High-density PVC or nylon shims

- Stainless steel screws (A2-70)

- Wall anchors (rated ≥ 30 kg)

Procedure:

- Establish a reference line using a laser level

- Pre-drill anchor points along the line

- Insert shims behind brackets as required

- Tighten fasteners progressively to avoid distortion

Technical Note:

Shim compression rate should be < 2% under load to prevent long-term sagging.

Method 2: Adjustable Bracket System (Preferred for B2B)

Best for: Commercial and institutional projects

Advantages:

- Precise leveling

- Faster installation

- Easier maintenance

Technical Parameters:

- Bracket spacing: 600–800 mm

- Maximum adjustment: ±12 mm

- Safety factor: ≥ 3:1

Method 3: Continuous Mounting Rail (Severely Uneven Walls)

Best for: Walls with inconsistent deviations

System Components:

- Continuous aluminum mounting rail

- Mechanical anchors

- Track clips mounted to rail

Benefits:

- Load distribution

- Reduced point stress

- Improved alignment accuracy

6. Anchor Selection for Uneven Wall Conditions

6.1 Common Wall Substrates

| Substrate | Recommended Anchor |

|---|---|

| Reinforced concrete | M6/M8 wedge anchor |

| Solid brick | Sleeve anchor |

| Hollow block | Chemical anchor |

| Metal stud | Toggle bolt (heavy-duty) |

| Drywall only | Not recommended |

6.2 Anchor Embedment Depth

- Minimum embedment: 40 mm

- Edge distance: ≥ 60 mm

- Spacing: ≥ 3× anchor diameter

Improper embedment is a leading cause of track failure.

7. Load Calculations & Dynamic Forces

Typical Commercial Curtain Loads

| Curtain Type | Weight (kg/m²) |

|---|---|

| Privacy curtain | 0.5–0.8 |

| Blackout curtain | 1.2–1.8 |

| Acoustic curtain | 2.5–3.5 |

Dynamic load factor:

Add 15–25% to account for curtain movement.

Total Design Load = Static Load × 1.25 (minimum)

8. Common Installation Mistakes on Uneven Walls

- Tightening brackets before leveling

- Using compressible materials as shims

- Over-spacing brackets

- Ignoring wall substrate differences

- Relying on curtain tension to “self-level”

Each of these shortens system lifespan and increases maintenance costs.

9. Maintenance Considerations in Commercial Settings

- Annual fastener torque check

- Visual inspection for shim creep

- Track alignment verification

- Roller replacement cycle: 3–5 years

Proper initial leveling significantly reduces maintenance frequency.

Conclusion: Installing Curtain Tracks on Uneven Walls the Right Way

Installing curtain tracks on uneven walls requires more than basic tools—it demands proper assessment, professional hardware selection, precise leveling techniques, and conservative load calculations. For B2B projects, using adjustable brackets, appropriate anchors, and rigid commercial-grade tracks ensures smooth operation, long-term reliability, and compliance with industry standards. Addressing wall irregularities correctly at the installation stage prevents costly maintenance issues and protects the integrity of the entire curtain track system.