Choosing the right curtain tracks is far more complex than it appears—especially for B2B buyers involved in commercial, hospitality, residential development, or large-scale interior projects. Curtain tracks are not merely accessories; they are load-bearing, functional systems that directly affect curtain performance, durability, and long-term maintenance costs.

This guide breaks down what to consider when buying curtain tracks, from material engineering and load capacity to installation methods and compliance standards, helping professional buyers make informed, risk-reduced purchasing decisions.

1. Understand the Application Scenario First (Commercial vs Residential)

Before evaluating any technical specification, B2B buyers must clearly define the end-use environment.

Common B2B Application Scenarios

- Hotels and serviced apartments

- Office buildings and conference centers

- Hospitals and healthcare facilities

- Retail and showroom spaces

- Large residential developments

Each scenario imposes different requirements on curtain track systems:

- Hotels prioritize silent operation and durability

- Hospitals require easy cleaning and antimicrobial compatibility

- Offices focus on straight-line precision and automation readiness

2. Load Capacity and Weight Tolerance (Often Overlooked)

One of the most critical technical parameters is maximum load capacity per meter.

Typical Load Ranges

| Track Type | Load Capacity |

|---|---|

| Standard aluminum track | 8–12 kg/m |

| Reinforced aluminum track | 15–30 kg/m |

| Steel-core track | 30–50 kg/m |

For heavy fabrics such as:

- Blackout curtains

- Acoustic curtains

- Thermal-lined drapes

A minimum safety factor of 1.5x is recommended in commercial installations.

Expert Tip: Always ask suppliers for static load test data and cycle fatigue test reports (≥10,000 cycles).

3. Material Selection: More Than Just Aluminum

Common Curtain Track Materials

- 6063-T5 aluminum alloy (industry standard)

- Powder-coated aluminum

- Anodized aluminum (≥10μm thickness)

- Steel-reinforced composite tracks

Why 6063-T5 Aluminum Matters

- High strength-to-weight ratio

- Excellent corrosion resistance

- Stable extrusion tolerance (±0.15mm)

For coastal or high-humidity projects, anodized finishes outperform painted tracks in long-term durability.

4. Track Design and Profile Structure

Not all curtain tracks are designed equally. Profile geometry directly impacts glide smoothness and noise control.

Key Design Factors

- Internal chamber shape (U-channel vs dual-track)

- Wall thickness (recommended ≥1.2mm for B2B)

- Reinforced ribs for long-span installations (>6m)

For large windows or ceiling-mounted systems, deflection resistance is critical to prevent sagging over time.

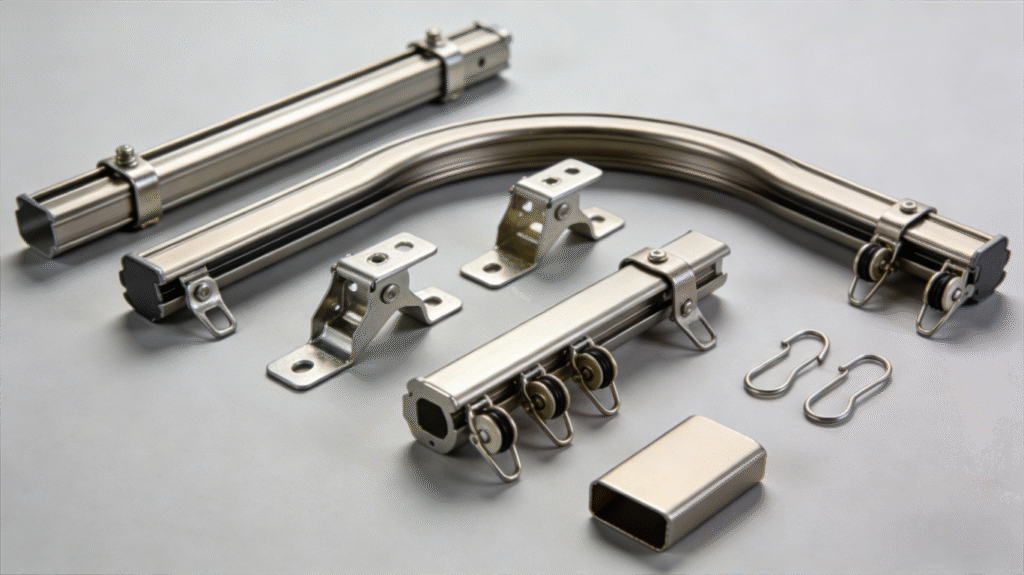

5. Curtain Track Accessories and Compatibility

A track system is only as strong as its weakest component.

Must-Evaluate Accessories

- Runners (nylon, POM, stainless steel)

- End stops with shock absorption

- Ceiling brackets vs wall brackets

- Curved connectors (radius ≥300mm recommended)

Low-quality runners significantly increase friction coefficient, leading to premature wear.

Professional buyers should request accessory compatibility lists to avoid mixed-system failures.

6. Manual vs Motorized Curtain Tracks

Automation is increasingly demanded in B2B projects.

Key Considerations for Motorized Tracks

- Motor torque rating (≥1.2Nm for heavy curtains)

- Noise level (<35 dB preferred)

- Control protocols (RS485, Zigbee, WiFi)

- Integration with BMS or smart hotel systems

Manual tracks should still allow future motor upgrades without full replacement.

7. Installation Method and Structural Compatibility

Improper installation negates even the best curtain track.

Installation Types

- Ceiling-mounted (concrete, gypsum board, metal frame)

- Wall-mounted with extension brackets

- Recessed ceiling track systems

For suspended ceilings, load distribution plates are strongly recommended.

Technical note:

Fastener spacing should not exceed 600mm for heavy-duty tracks.

8. Compliance, Certifications, and Quality Assurance

B2B buyers must verify compliance with regional standards.

Common Certifications

- ISO 9001 (manufacturing quality)

- SGS load testing

- RoHS compliance

- Fire retardant compatibility (for public buildings)

Request batch traceability and material certificates for large orders.

9. Supplier Capability and Long-Term Support

Beyond the product itself, evaluate the supplier’s engineering and service capability.

What Professional Buyers Should Assess

- OEM/ODM experience

- Custom extrusion capability

- MOQ flexibility for projects

- Lead time stability

- After-sales technical support

A reliable curtain track supplier should provide technical drawings, CAD files, and installation guides.

10. Cost vs Lifecycle Value (Not Just Unit Price)

Cheapest options often result in:

- Higher maintenance frequency

- Premature replacement

- Customer complaints in hospitality projects

A lifecycle-based evaluation considers:

- Expected service life (≥8–10 years)

- Maintenance costs

- Replacement downtime

Conclusion: Making the Right Curtain Track Purchase Decision

When buying curtain tracks for B2B applications, the decision goes far beyond appearance or price. Load capacity, material engineering, accessory compatibility, installation methods, and supplier reliability all play decisive roles in long-term performance and project success.

By carefully evaluating these factors—and working with technically capable suppliers—professional buyers can ensure durable, compliant, and future-proof curtain track systems that deliver consistent value across their projects.